McPherson Engineering Enterprises LLC Project

Fuel quality analyzer

October 2016

Responsibilities include:

• Requirements generation and development with engineering team and customer

• Full systems engineering and design

• Opto-mechanical and mechanical design

• Optical layout

• Custom housing design including customer provided color scheme and labeling

• Cuvette sample chamber design

• Full engineering document package and draft manufacturing documentation

• Assembly of 7 prototype systems including bread board for future R&D based on this design

• Aided in generation of test plan

Product Details:

• Spectroscopically measures color and a standardized version of opacity (haze) of fuels for quality measurement and verification

• Molded plastic housing and full optical chamber designed to withstand the harsh characteristics of various fuels

• 350-900nm spectral range

• 2 on board light sources across multiple optical paths

• Light tight optical chamber for cuvette based fluidic measurement

• Utilizes and detects 3 different cuvette sizes for various fuel types

• Internal system test to indicate presence of contamination and verify accuracy of each measurement

• On board PC and touch screen with membrane display and additional user buttons

• Designed for ease of use and minimal button pushes by operator for measurement

• Envelope: 14” X 14” X 13”

Spectrometer Superbench assembly

April 2016

Responsibilities included:

• Complete system design of Superbench assembly

• Custom housing design

• Engineering and manufacturing documentation

• Assembly of 7 prototype systems

Product Details:

• Superbench assembly contains 5 spectrometers and 2 light sources, all optically coupled together for single point use

• 200nm to 1700nm spectral range

• Integrated power supplies for all components and USB hub for communication

• 4 months from project inception to delivery

• Envelope: 20” X 18” X 16”

Superbench featured on CBS News on the About page.

Prototype Design for Laser Surgery System

Ongoing

Responsibilities include:

• Provide FDA required engineering document package

• System Design including systems and industrial engineering

• Integration of all components

• Consideration for cooling and air flow

• Implementation of customer requirements (shape, casters, laser, chiller, etc.)

• Opto-mechanical design for laser delivery through external SMA

Product Details:

• SMA fiber output with external fiber sensing

• Switch membrane control display

• Thulium Laser ~2000nm

• Secondary indicating laser coaxial with Thulium laser

• Laser focus into variable fiber options

• Swivel Casters

• Removable skins for easy access and service to internal components

• External footswitch control, emergency shutoff, key switch, power cord,

bumpers, and handles

• Internal power distribution, system control, laser, chiller, laser fiber, indicator

laser, and coaxial laser combining optical assembly with focus into SMA

• Envelope: 35.5” X 34” X 22.7”

Long range / dynamic spectrometer system for education

April 2016

Responsibilities included:

• Complete system design

• Optical layout

• Documentation

• Assembly

• Functional test

Product Details:

• 200nm to 1700nm spectral range

• Resolution down to 0.08nm

• 3 interchangeable detector options within a single system

• 4 grating turret to provide spectral range and resolution variances

• On the fly alignment capability for any configuration within defined parameters including easy ergonomic access for educators and students

• USB 2.0 interface with 12V power for cooled detector option (900-1700nm range detector)

• Envelope: 12” X 12” X 6”

• SMA 905 input interface with adjustable slit widths from 25 to 200 micron

including optional filter for 785nm RAMAN measurement

• Hinged lid and external grating rotation adjustment for ease of use

• Project kickoff to delivery in < 6 weeks

Emissions Monitor Subassembly

January 2015

Responsibilities included:

• Develop and define system requirements

• Opto-mechanical design

• Optical layout

• Project engineering

• Full transfer to manufacturing

• Tooling

• Customer interface

Product Details:

• 200nm to 650nm spectral range

• Designed to interface to bifurcated optical fiber and probe assembly for

emissions transmission measurement

• Off the shelf, pulsed Xenon light source

• Field replaceable light source with quick eject for light source change

in < 1 minute

• SPI communication to EMBED spectrometer (2013 design project

http://oceanoptics.com/product/embed-spectrometer/ )

• Envelope: 7.5” X 4” X 4”

• SMA 905 input interface to spectrometer, custom light source to fiber interface for optimal throughput

Dale McPherson Projects

Liquid Authenticator Pelicase System

December 2014

Responsibilities included:

• Project engineering

• Develop and define system requirements

• Opto-mechanical system design

• Optical layout

• Cost analysis

• Complete documentation package

• Full transfer to manufacturing

• Quality requirements definition

• Tooling

• Customer interface

Product Details:

• Fluidic cell measurement system with optical path lengths ranging from 0.2mm to 20mm utilized for absorbance measurement

• Single spectrometer and source utilized for 3 fluidic channel measurement system

• Deuterium / Halogen light source with field replaceable bulb

• Embedded laptop PC

• Custom SMA 905 fiber optic assemblies

• 220nm to 450nm spectral range

• USB 2.0 interface with 120V AC power

• Envelope: 18-1/2" X 14” X 7"

• 3 channel fluidic input and output ports

• System temperature and bulb life monitoring

• For more information: http://oceanoptics.com/product-category/integrated-systems/

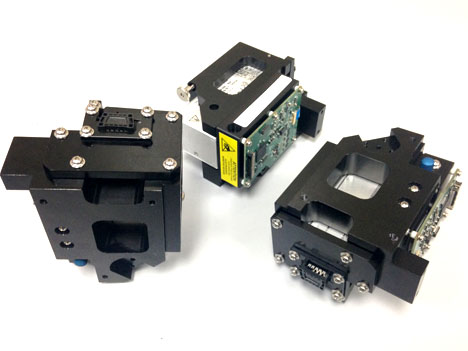

Prostate Biopsy Detection Subassembly

November 2014

Responsibilities included:

• opto-mechanical system design

• complete documentation package

• customer interface

• requirements development

• test and manufacturing documentation

• assembly, test, and delivery

Product Details:

• Quantity 2 prototype systems delivered

• Spectrometer and light source subassembly

• Custom SMA 905 fiber optic assemblies

• 220nm to 650nm spectral range (custom ranges available)

• Custom light source, 3 source co-axial focused into fiber through SMA port.

• Extreme light source stability and lifetime requirements

• On board photodiode feedback and temperature controller for sources

• 12V DC power

• Envelope: 15-1/2" X 10-1/4” X 3-1/2"

Additional Projects (more details may be furnished upon request):

• Slit alignment station for improved spectrometer slit accuracy and streamline of manufacturing. Increased accuracy by 50% and repeatability by 100%, increased throughput by 75%.

• NIRQuest project program manager and systems engineer. http://oceanoptics.com/product/nirquest-custom/

• Automated test fixture for largest volume OEM for reduced field failures and streamline of manufacturing. Increased accuracy of test results by 80%, reduced field failures by 60%.

• Laser resonator redesign for efficiency and reduce field failures. Increased throughput power by 20%, increased rep rate by 10%, reduced field failures by 50%.

*SEE RESUME FOR ADDITIONAL PROJECT AND EXPERIENCE INFORMATION

© 2015 McPherson Engineering Enterprises, LLC.